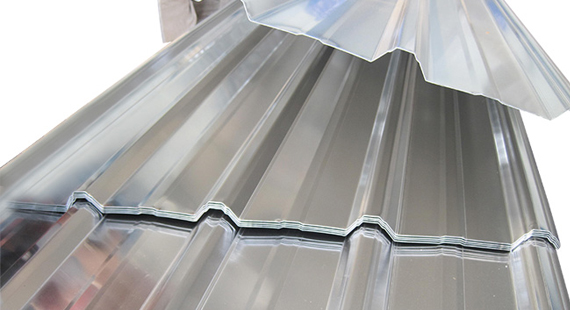

Are you in the process of choosing roofing sheets for your new building? It can be a daunting task, considering the wide range of options available. Two popular choices in the market are Aluzinc and Aluminium roofing sheets. Both of these materials offer their own set of advantages and considerations. From durability and longevity to cost comparison and installation process, there are multiple factors to take into account. In this discussion, we will explore the key differences between Aluzinc and Aluminium roofing sheets, helping you make an informed decision that suits your building’s needs. So, let’s dive into the world of roofing materials and find out which one is better for you.

Durability and Longevity

When it comes to durability and longevity, Aluzinc roofing sheets outperform aluminium roofing sheets. Aluzinc, a combination of aluminum, zinc, and silicon, offers superior resistance to weather conditions compared to pure aluminium. This resistance ensures that Aluzinc roofing sheets can withstand harsh elements such as rain, wind, and UV rays without deteriorating quickly.

In terms of lifespan, Aluzinc roofing sheets have a significantly longer life expectancy than aluminium sheets. Aluzinc can last up to four times longer, with an estimated lifespan of 50 to 60 years. On the other hand, aluminium roofing sheets generally have a lifespan of around 15 to 20 years.

The key factor behind the durability and longevity of Aluzinc roofing sheets is the protective properties of zinc. Zinc acts as a sacrificial layer, preventing corrosion and protecting the underlying layers of the sheet. This protective layer ensures that the Aluzinc sheets remain intact and resistant to weathering.

Cost Comparison

Now let’s move on to comparing the cost of Aluzinc and aluminium roofing sheets. When it comes to cost effectiveness, Aluzinc roofing sheets have an advantage over aluminium sheets. Aluzinc sheets are generally more affordable than aluminium sheets, making them a cost-effective choice for many builders and homeowners.

In addition to being cost-effective, Aluzinc roofing sheets also offer energy efficiency benefits. The combination of zinc and aluminum in Aluzinc sheets provides excellent heat reflection properties, helping to keep the building cooler during hot weather. This can result in lower energy consumption and reduced cooling costs.

On the other hand, while aluminium roofing sheets may be more expensive upfront, they do offer long-term cost savings. Aluminium is a durable and corrosion-resistant material that requires minimal maintenance. It is also lightweight, which can make installation easier and potentially reduce labor costs.

When considering the cost of roofing sheets, it is important to weigh the initial investment against long-term savings. While Aluzinc sheets may be more cost-effective upfront, aluminium sheets may provide greater durability and longevity, resulting in potential savings over time.

Ultimately, the choice between Aluzinc and aluminium roofing sheets will depend on your budget, preferences, and specific needs. It is advisable to consult with roofing professionals to determine the most suitable option for your building.

The installation process for both Aluzinc and aluminium roofing sheets is straightforward and can be completed with ease. When it comes to installation time, both materials offer efficiency. Aluzinc roofing sheets are lightweight, making them easier to handle and install. They can be easily cut and shaped to fit the specific dimensions of your roof, reducing installation time. On the other hand, aluminium roofing sheets are also lightweight, making them easy to transport and handle during installation. Their flexibility allows for quick and precise installation, saving time and effort.

However, regardless of the material chosen, safety precautions must be taken during the installation process. It is important to ensure that the installation is carried out by trained professionals who are familiar with the necessary safety measures. These measures may include the use of safety harnesses, protective clothing, and proper equipment to prevent accidents. Additionally, it is crucial to follow the manufacturer’s guidelines and recommendations for installation to ensure a secure and durable roofing system.

Maintenance and Repairs

Maintenance and repairs for both Aluzinc and aluminium roofing sheets are essential for ensuring the longevity and durability of your roof. Regular roofing inspections are crucial to identify any potential issues and address them promptly. Common issues that may arise with both types of roofing sheets include corrosion, leaks, and loose or damaged panels.

To maintain your Aluzinc or aluminium roof, it is recommended to inspect it at least twice a year, preferably in spring and fall. During these inspections, check for any signs of corrosion, such as rust or discoloration, and make sure all panels are securely fastened. Additionally, be on the lookout for any leaks or water stains on the ceiling, as these can indicate a problem with your roof.

When it comes to repairs, it is important to address any issues as soon as they arise. For Aluzinc roofing sheets, if you notice any corrosion, it is crucial to remove the affected area and apply a suitable corrosion-resistant coating. Similarly, for aluminium roofing sheets, any loose or damaged panels should be replaced or repaired promptly to prevent further damage.

When considering the environmental impact, it is important to evaluate the sustainability of both Aluzinc and aluminium roofing sheets. When it comes to recyclability, aluminium roofing sheets have a clear advantage. Aluminium is a highly recyclable material, meaning that it can be reused multiple times without losing its properties. This reduces the demand for new aluminium production and helps to conserve natural resources. On the other hand, Aluzinc roofing sheets, which are made from a combination of steel and zinc, are not as easily recyclable. While steel can be recycled, the presence of zinc complicates the process and makes it less efficient.

In terms of carbon footprint, aluminium roofing sheets also come out on top. The production of aluminium requires a significant amount of energy, resulting in higher greenhouse gas emissions. However, the long lifespan and recyclability of aluminium roofing sheets offset this initial carbon footprint. On the other hand, the production of Aluzinc roofing sheets involves a process called hot-dip galvanization, which also releases greenhouse gases. Additionally, the steel component of Aluzinc roofing sheets contributes to higher carbon emissions compared to aluminium.

Frequently Asked Questions

Are There Any Color Options Available for Aluzinc and Aluminium Roofing Sheets?

When it comes to color options, both aluzinc and aluminium roofing sheets offer a wide range of choices. You can find various colors for both materials, allowing you to match your building’s aesthetic preferences. However, it’s important to consider the pros and cons of using colored roofing sheets. While they can enhance the overall appearance of your building, colored sheets may require more maintenance and can be more prone to fading over time.

Can Aluzinc and Aluminium Roofing Sheets Be Used for Both Residential and Commercial Buildings?

Aluzinc and aluminium roofing sheets are versatile options for both residential and commercial buildings. Aluzinc sheets offer several advantages, including excellent corrosion resistance and durability. On the other hand, aluminium sheets have some drawbacks, such as being more prone to denting and higher cost. However, both types of roofing sheets can be a suitable choice depending on your specific needs and preferences. Consider the advantages of aluzinc and the disadvantages of aluminium when making your decision.

Is There a Difference in the Noise Levels Between Aluzinc and Aluminium Roofing Sheets?

There is a difference in noise levels between aluzinc and aluminium roofing sheets. The choice of roofing material can impact the energy efficiency of a building. Aluzinc roofing sheets have better insulation properties, reducing noise levels from rain and hail. This can result in lower energy consumption for cooling or heating. In terms of long-term cost comparison, both materials offer durability and low maintenance. However, aluzinc roofing sheets may provide better value for money due to their superior insulation properties.

Can Aluzinc and Aluminium Roofing Sheets Withstand Extreme Weather Conditions Such as Heavy Rain or Hailstorms?

In extreme weather conditions, both aluzinc and aluminium roofing sheets are known for their durability. They can withstand heavy rain and hailstorms without significant damage. When it comes to cost, aluzinc roofing sheets are generally more affordable compared to aluminium. However, it’s important to consider other factors such as longevity and maintenance requirements before making a decision. Ultimately, it’s advisable to consult with roofing experts to determine the best option for your building.

Are There Any Specific Precautions to Take During the Installation Process of Aluzinc and Aluminium Roofing Sheets to Ensure Their Longevity?

When installing aluzinc and aluminium roofing sheets, it’s important to take certain precautions to ensure their longevity. Make sure the sheets are properly aligned and securely fastened to prevent any potential leaks or damage. Additionally, use appropriate tools and equipment for installation to avoid unnecessary stress on the sheets. Once installed, regularly inspect and maintain the roofing sheets to identify any issues and address them promptly. Following these precautions and maintenance tips will help maximize the lifespan of your aluzinc or aluminium roofing sheets.

Conclusion

In conclusion, when considering roofing options for your building, both aluzinc and aluminium sheets have their own advantages. Aluzinc sheets offer superior durability and longevity, while aluminium sheets are cost-effective and easy to install. Maintenance and repairs may vary, but both materials are environmentally friendly. Ultimately, the choice depends on your specific needs and budget. Consider consulting with a professional to determine the best option for your building.

Discover more from Ghana Scoop

Subscribe to get the latest posts sent to your email.